Overview

The article titled “How to Manufacture a Product: A Step-by-Step Guide for Beginners” is designed to support you through the often overwhelming manufacturing process. We understand that starting this journey can be daunting, and we are here to help you navigate it with confidence. This guide highlights essential steps for beginners, starting with the development of your product concept, where your ideas begin to take shape.

As you progress, the importance of designing and prototyping cannot be overstated. This phase is not just about creating a product; it’s about bringing your vision to life. Crafting a business plan follows, which can feel like a monumental task, but remember, you are not alone in this. Securing funding is another critical phase, and while it may seem challenging, there are resources available to assist you. Finally, validating your product for market readiness is crucial, ensuring that what you’ve created meets the needs of your potential customers.

Each of these stages plays a vital role in ensuring successful product development and market entry. By understanding the emotional impacts of these challenges and embracing the solutions provided, you can move forward with hope and determination. Remember, with each step you take, you are one step closer to making your dream a reality.

Introduction

In the ever-evolving landscape of product manufacturing, we understand that turning raw materials into innovative solutions can feel overwhelming. It requires not only creativity but also a profound grasp of the key concepts that underpin the entire process. Aspiring manufacturers often face a complex maze of challenges and opportunities, from mastering supply chain management to ensuring quality control. As trends like electrification and sustainability reshape our industry, the importance of strategic planning and effective execution becomes clearer than ever.

You are not alone in navigating these waters. This article seeks to empower you by outlining the essential steps of product development, guiding you from the initial spark of conceptualization to the readiness for market launch. Together, we will explore the knowledge and strategies you need to thrive in today’s competitive manufacturing environment, fostering a sense of ownership over your career path. Let’s embark on this journey of transformation and growth, where your aspirations can truly take flight.

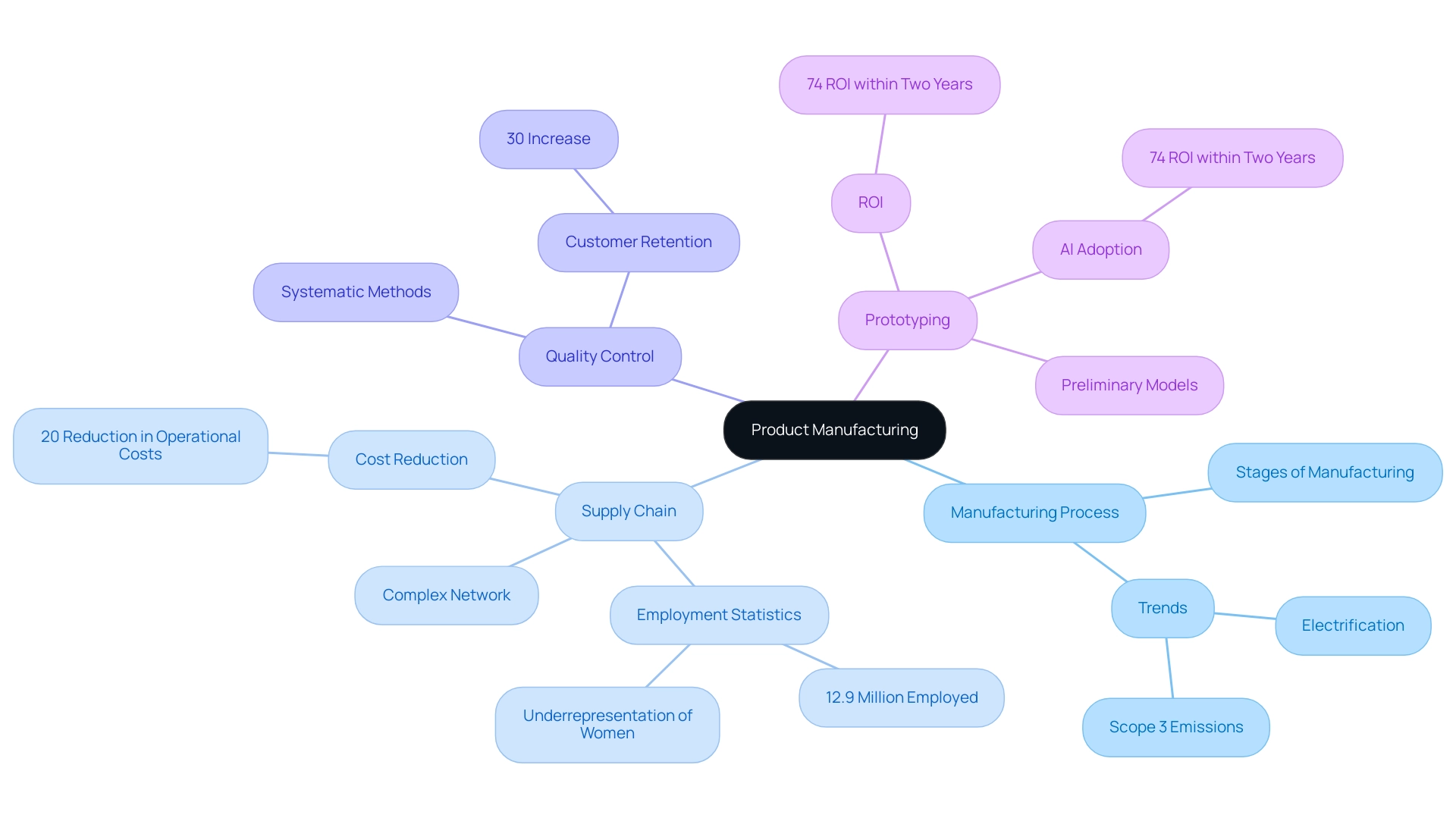

Understanding Product Manufacturing: Key Concepts and Definitions

Product manufacturing is a multifaceted journey, transforming raw materials into finished goods through a series of well-defined steps. For anyone aspiring to navigate this process, grasping the following key concepts is essential.

Manufacturing Process: This journey encompasses everything from initial conception through design, production, and final assembly. Each stage is crucial in ensuring that the end product not only meets market demands but also adheres to quality standards. Since January 2020, we’ve seen a rise in discussions around ‘electrification’ and ‘scope 3 emissions,’ reflecting trends that are vital for aspiring producers to understand.

Supply Chain: The supply chain is a complex web of suppliers, manufacturers, and distributors. Effective management of this network is vital, as it directly influences production efficiency and cost-effectiveness. Recent trends show that organizations focusing on optimizing their supply chains can significantly enhance their operational performance. In fact, companies that adopt advanced supply chain strategies have reported a 20% reduction in operational costs. As of June 2024, approximately 12.9 million people are employed in production in the U.S., with significant roles in transportation equipment and food production. However, it’s important to acknowledge that women remain underrepresented in the workforce and leadership positions.

Quality Control: This refers to the systematic methods established to ensure that products meet specific standards and requirements. Quality control is not merely a final check; it is integrated throughout the manufacturing cycle to prevent defects and ensure customer satisfaction. Companies that prioritize quality often experience a 30% increase in customer retention rates, a testament to the importance of this practice.

Prototyping: Developing a preliminary model is essential for testing and refining design before mass production. Prototyping allows manufacturers to identify potential issues early, saving time and resources. The typical return on investment (ROI) for organizations that incorporate prototyping into their development methodology is reported to be 74% within two years. This highlights its effectiveness in reducing costs and enhancing quality. Additionally, organizations adopting AI in production also report an ROI of 74% within the same timeframe, underscoring the financial benefits of modernizing production processes.

Understanding these essential concepts not only equips aspiring producers with the knowledge necessary for successful manufacturing but also empowers them to leverage current trends and technologies in the industry. As Christine Evans, Sr. Director of Marketing at Fictiv, shares, “I’m passionate about sharing the stories of amazing hardware entrepreneurs and innovators,” highlighting the significance of narrative in the production sector. Furthermore, geopolitical factors, such as trade tensions and the Russia-Ukraine war, could impact the manufacturing market in 2023. Staying informed about these developments is crucial for aspiring manufacturers, as you are not alone in navigating these challenges.

Step 1: Developing Your Product Concept

To effectively develop your concept, it’s essential to consider a few important steps that can guide you through the process.

- Identify a Problem: Begin by pinpointing a specific issue that your item aims to address or a need it seeks to fulfill. Understanding this issue is crucial, as it lays the foundation for your offering’s significance in the market.

- Investigate the Industry: Conduct a thorough analysis to evaluate current offerings. This involves identifying gaps that your offering can fill, which is vital for ensuring its uniqueness and potential success. Did you know that nearly 70% of new items fail due to a lack of market need? This statistic underscores the importance of this step. For example, the Magnet is a magnetic bag holder that provides convenience in various settings, illustrating how addressing a specific need can lead to success.

- Define Your Target Audience: Take the time to deeply understand who will benefit from your offering. Tailoring your concept to meet the specific needs and preferences of your target audience can significantly enhance its appeal and marketability.

- Create a Concept Statement: Draft a concise description of your offering, outlining its purpose and unique selling points. This statement serves as a guiding document, ensuring that your idea remains focused and aligned with market demands.

Additionally, consider enhancing your skills in managing offerings through resources like the free Mobile App Management Certification course. This course equips individuals with essential knowledge and tools for success in this field. It aligns closely with the tailored coaching method of The Entrepreneur’s Source, which empowers clients to navigate their career transitions successfully.

By following these steps and integrating practical insights, you can ensure that your concept is not only feasible but also strategically positioned for success in the competitive industrial landscape. Remember, you are not alone in this journey, and with the right support and resources, you can achieve your aspirations.

Step 2: Designing and Prototyping Your Product

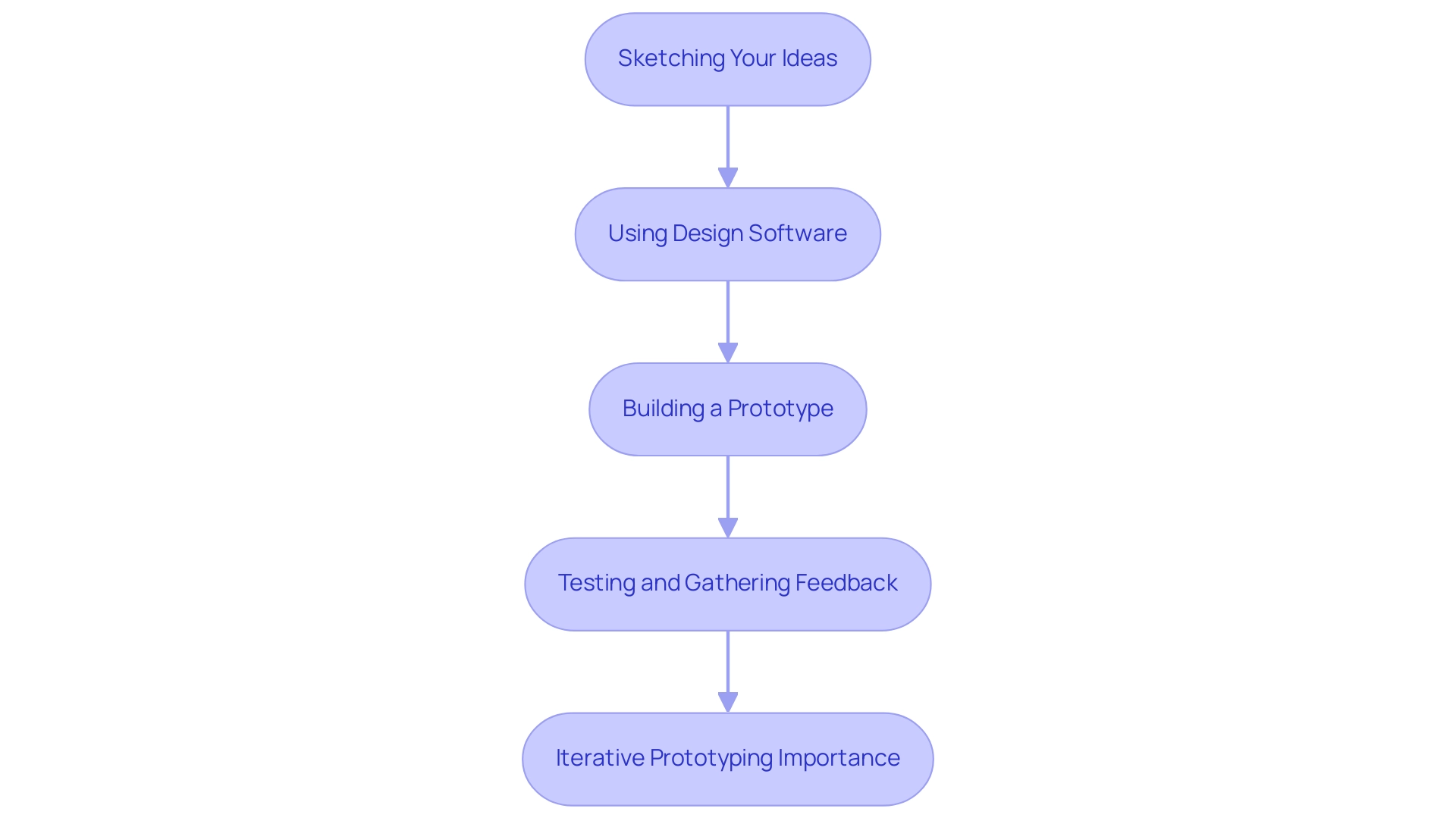

Designing and prototyping your product is a crucial phase in the manufacturing process, encompassing several key steps that can feel overwhelming at times.

-

Sketching Your Ideas: Begin by creating rough sketches of your item. This initial visualization helps clarify your design concept and functionality, allowing you to explore various ideas before committing to a specific direction. Remember, this is a safe space for creativity, where every idea counts.

-

Using Design Software: Transition from sketches to detailed digital models by utilizing Computer-Aided Design (CAD) software. CAD tools not only enhance precision but also facilitate collaboration among teams. For example, at Pivot International, CAD facilitates smooth exchange of information and models among engineering, supply chain, and production teams, which is crucial for effective development. The global supply chain team at Pivot sources parts efficiently after finalizing designs and generating Bills of Materials (BOMs), demonstrating how to manufacture a product while highlighting the practical implications of the design process. This collaborative effort can ease your worries about the complexities of product development.

-

Building a Prototype: Once your design is finalized, develop a physical prototype using materials that closely resemble those intended for the final item. This step is vital as it allows you to assess the item’s look, feel, and functionality in a tangible form. It’s a moment to see your vision come to life, which can be incredibly fulfilling.

-

Testing and Gathering Feedback: Conduct thorough testing with potential users to gather valuable feedback on your prototype. This iterative process is essential for enhancing your offering, ensuring it aligns with user expectations and industry demands. We understand that receiving feedback can be daunting, but it’s a crucial step toward improvement and success.

The significance of prototyping in development cannot be overstated. Studies indicate that offerings developed through iterative prototyping have a significantly higher success rate in the market. By adopting this method, you not only improve the quality of your final outcome but also lessen the likelihood of expensive redesigns later on.

In 2025, the latest CAD software options continue to evolve, offering advanced features that streamline the design process and improve collaboration. Examples of popular CAD software include SolidWorks, AutoCAD, and Fusion 360, each offering unique tools designed for different aspects of design. By utilizing these technologies, you can ensure that your product design is not only innovative but also practical for how to manufacture a product.

As you navigate this process, remember that transitioning to career ownership can empower you to achieve your career goals. As Parnell Woodard, a Career Ownership Coach, emphasizes, “The journey to career ownership is about taking control of your professional future.” This mindset is crucial as you explore the production landscape and seek to establish your own venture.

Furthermore, The Entrepreneur’s Source offers a comprehensive and personalized approach to career coaching, which can be invaluable as you embark on this new path. You are not alone in this journey; support is available to help you thrive.

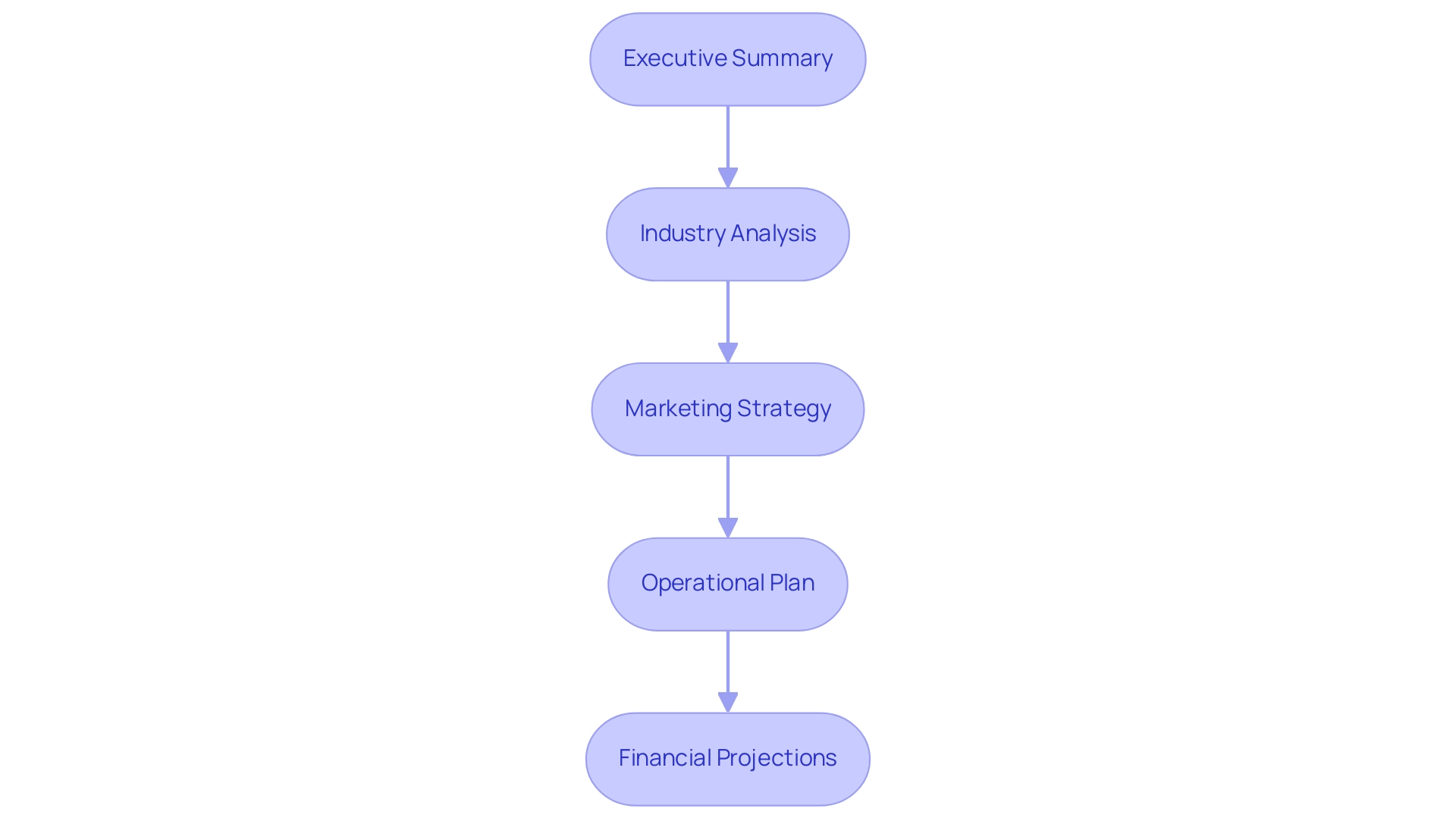

Step 3: Crafting a Comprehensive Business Plan

Creating a robust business plan for your manufacturing startup can feel overwhelming, but you’re not alone in this journey. It’s essential to include several key sections that will guide you toward success.

-

Executive Summary: Start with a brief outline of your business idea. What product do you plan to produce? What unique value does it offer to consumers? A well-crafted executive summary captures the essence of your vision and sets a positive tone for the rest of your plan.

-

Industry Analysis: Understanding your target audience is crucial. Who are they? What do they need? By conducting thorough research on demographics and purchasing behaviors, you can gain valuable insights. Analyzing competitors and industry trends will help you navigate the landscape of your business. Remember, startups with a strong industry analysis are 30% more likely to secure funding. Just look at successful startups like Calm and Headspace, which together boast a valuation of about $5 billion. This highlights the potential success of a well-planned venture.

-

Marketing Strategy: How will you promote and sell your product? Clearly outlining your approach, including marketing channels and pricing strategy, is vital. Incorporating insights from your industry analysis can enhance your strategy, as many successful startups effectively leverage data to inform their marketing decisions.

-

Operational Plan: Detailing how to manufacture your product is essential. What equipment and technology will you need? What about human resources? This section should also outline timelines and address logistical considerations. A comprehensive operational plan not only guides your daily activities but also reassures potential investors of your preparedness. Consider the dynamics of your startup team; teams that blend experience with passion often perform better, significantly boosting your chances of success.

-

Financial Projections: Providing realistic estimates of startup costs and revenue streams is critical. This section demonstrates the financial viability of your venture. Statistics show that startups with detailed financial projections are more likely to meet their funding goals. Additionally, as technology becomes increasingly vital for financial management, incorporating these tools into your projections is essential. Assessing your readiness to handle industry-specific risks using tools like a Risk Profile can further enhance your risk management strategies.

By thoughtfully crafting each of these sections, your business plan can serve as a strategic roadmap for your venture, significantly enhancing your chances of success in a competitive market. Remember, as Tony Hsieh, CEO of Zappos, wisely said, “Chase the vision, not the money; the money will end up following you.” You have the power to create a fulfilling and successful journey ahead.

Step 4: Securing Funding for Your Manufacturing Venture

Securing funding for your production venture is a critical step that can significantly influence your success. We understand that this process can feel overwhelming, but there are several viable options to consider:

-

Personal Savings: Utilizing your own savings, including checking and savings accounts, can be a straightforward way to fund the initial stages of development. This option allows you to maintain full control over your business without incurring debt or giving away equity. However, we recognize that it also carries the risk of personal financial strain.

-

Loans: Business loans from banks or credit unions can provide substantial capital for your production startup. While this option allows you to retain ownership, it often requires a solid business plan and collateral. Interest rates and repayment terms can vary, so it’s essential to shop around for the best deal. The SBA Lender Match service can simplify this process by connecting small businesses with potential lenders, allowing you to compare rates, terms, and fees efficiently.

-

Investors: Engaging with angel investors or venture capitalists can be an effective way to secure funding. These investors not only provide capital but can also offer valuable industry insights and connections. In 2022 alone, investors infused over $30 billion into blockchain initiatives, highlighting the potential for investment in manufacturing ventures. However, be prepared to share a portion of your business equity and possibly relinquish some control over decision-making.

-

Crowdfunding: Initiating a crowdfunding campaign can be a creative method to gather funds while simultaneously confirming your concept. Successful campaigns have raised millions, with platforms like Kickstarter and Indiegogo showcasing numerous instances of items that gained traction through community support. In fact, the success rate of crowdfunding campaigns for new products has been steadily increasing, with many campaigns achieving their funding goals within days. However, it’s crucial to understand the pros and cons of this approach, including the need for effective marketing and the potential for public scrutiny.

Each funding option presents unique advantages and challenges. As Parnell Woodard, a Career Ownership Coach at Find Your Career 2.0, emphasizes, transitioning to career ownership is a vital journey, and securing funding plays a crucial role in that process. By carefully evaluating these choices and recognizing the importance of learning from other businesses’ failures, you can determine the best fit for your manufacturing venture, ensuring a solid foundation for your business’s growth. Additionally, startups are increasingly adopting technology for financial management and personalized marketing, which can enhance your funding strategy.

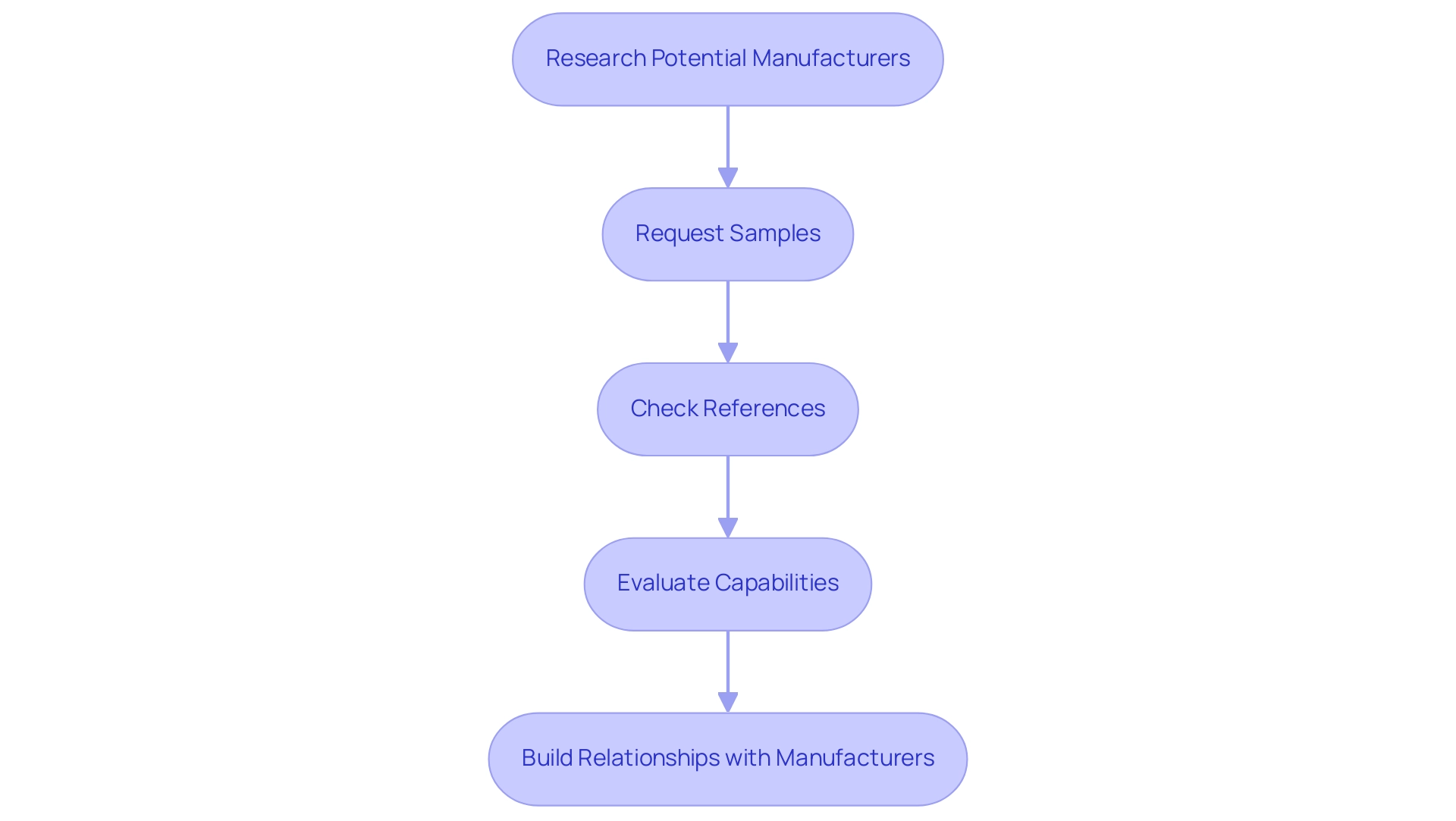

Step 5: Finding the Right Manufacturer for Your Product

Finding the right manufacturer for your product can feel overwhelming, but you are not alone. To navigate this journey successfully, consider these essential steps:

-

Research Potential Manufacturers: Begin by identifying manufacturers with a proven track record in your specific category. This foundational step ensures that you partner with a company that understands the nuances of your industry.

-

Request Samples: Evaluate the quality of potential manufacturers by requesting samples of their previous work. This hands-on assessment allows you to gauge craftsmanship and suitability for your product.

-

Check References: Engage with other clients who have worked with the manufacturer. Their feedback will provide valuable insights into the manufacturer’s reliability, communication, and overall satisfaction.

-

Evaluate Capabilities: Confirm that the manufacturer can meet your production requirements, including volume and timelines. This evaluation is crucial to ensure that they can scale with your business needs.

Building strong relationships with manufacturers is vital for navigating risks and achieving long-term success in procurement. Recent trends indicate that 53% of suppliers are willing to provide additional information if the collaboration process is improved. This statistic emphasizes the significance of fostering these partnerships, as shown by the case study titled “Willingness of Suppliers to Engage,” which demonstrates that improved communication and engagement between suppliers and buyers can result in better cooperation and support, ultimately benefiting both parties in a fluctuating environment.

As David Andrea, a principal at Plante Moran, emphasizes, “Remember, your suppliers are the key to greater agility and resilience. But it’s up to you to nurture these partnerships and unlock their full potential.”

By following these steps and fostering effective communication with your production partners, you can significantly enhance your chances of success in understanding how to manufacture a product and bringing it to market, especially as you navigate your career transition.

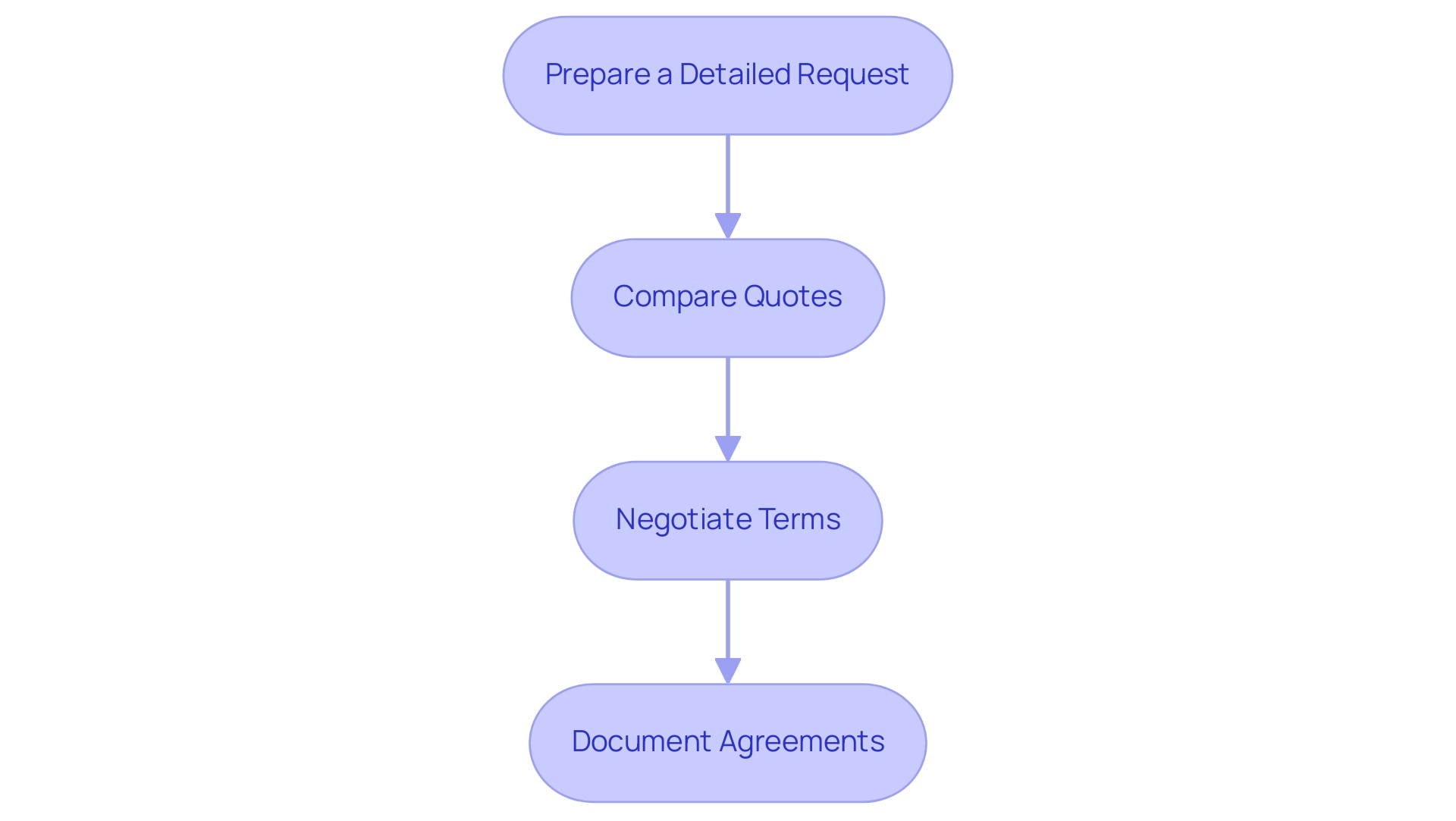

Step 6: Requesting Quotes and Setting Terms

When seeking quotes and establishing terms with manufacturers, it’s important to approach the process with care and structure to ensure clarity and effectiveness.

-

Prepare a Detailed Request: Crafting a comprehensive Request for Quote (RFQ) is essential. This document should clearly outline specifications, quantities, and timelines. A well-prepared RFQ not only streamlines the quoting process but also increases the likelihood of receiving accurate and competitive quotes.

-

Compare Quotes: Once you receive quotes from various manufacturers, take a moment to evaluate them thoroughly. Comparing quotes allows you to identify the best value, considering not just the price but also the quality of materials and services offered. Have you ever noticed how companies that engage in this comparative analysis often secure better agreements? It’s true; they improve their overall efficiency. In fact, those who adopt a strategic approach to RFQs and negotiations often experience a significant increase in successful contract outcomes, solidifying their position in the competitive production landscape.

-

Negotiate Terms: Effective negotiation is key to establishing favorable terms. Discuss critical aspects such as payment schedules, delivery timelines, and quality control methods. Engaging in open conversation can lead to mutually advantageous agreements that enhance the production process. As Parnell Woodard, a Career Ownership Coach, emphasizes, transitioning to career ownership empowers individuals to take control of their professional futures. This empowerment mirrors the benefits gained through effective negotiation in manufacturing.

-

Document Agreements: It’s vital to formalize all negotiated terms in a written contract. This documentation serves to protect both parties and ensures clarity and enforceability of all agreed-upon conditions. Furthermore, following designated procurement routes is crucial to prevent unauthorized spending, which can lead to inefficiencies and higher expenses.

By adhering to these steps, you can improve your negotiation results, leading to better pricing and terms that positively influence your production activities. Remember, you are not alone in this journey. The Entrepreneur’s Source has helped hundreds of thousands navigate their career transitions, showcasing the effectiveness of personalized coaching in achieving successful outcomes. This approach resonates not only in career ownership but also within the manufacturing sector, where strategic engagement can lead to better business results.

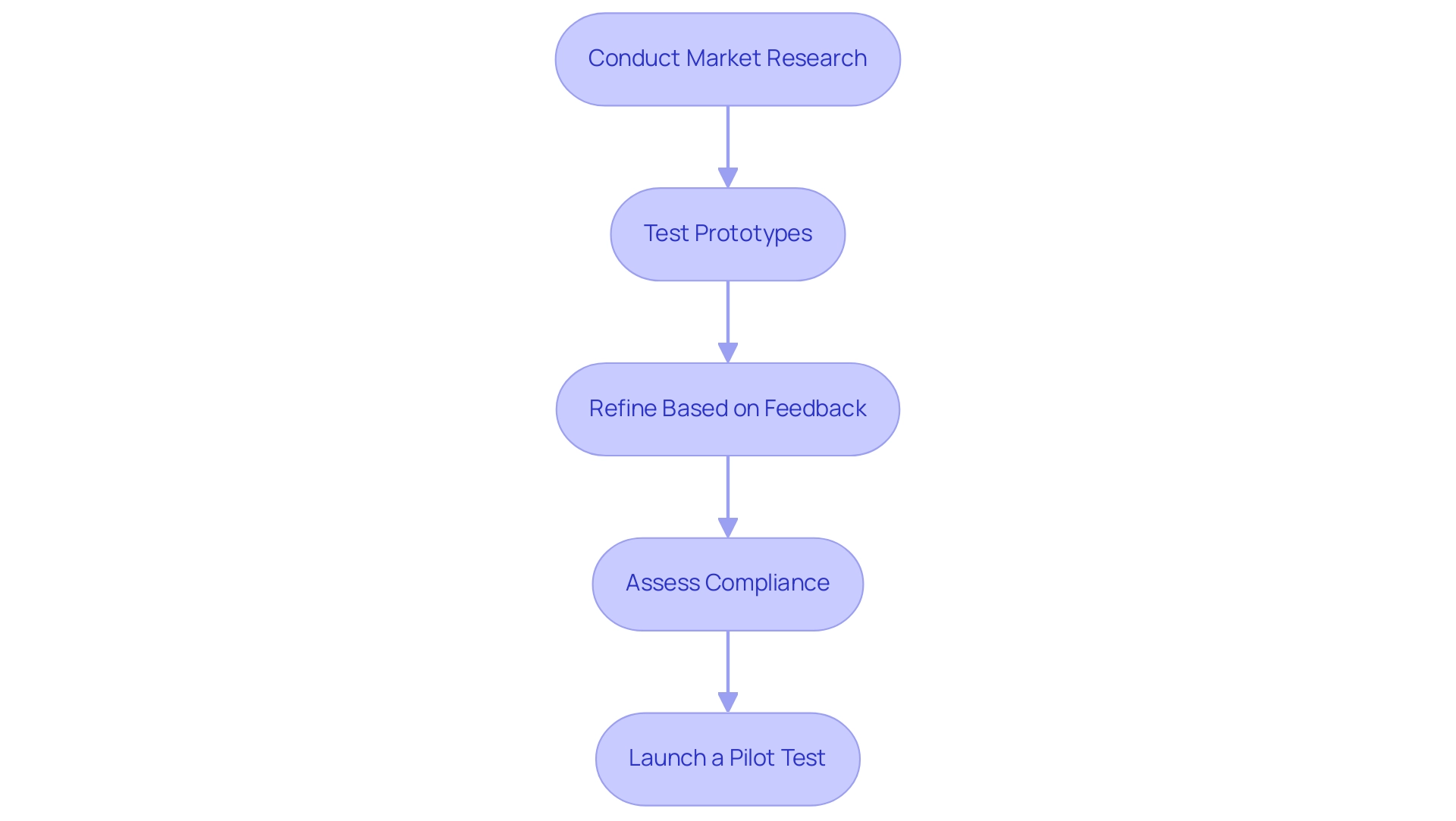

Step 7: Validating Your Product for Market Readiness

To effectively validate your product for market readiness, it’s essential to follow these steps with care and consideration:

-

Conduct Market Research: Begin by gathering insights from potential customers regarding your concept. We understand that this can feel overwhelming, but utilizing techniques such as surveys, interviews, and focus groups can really help you understand customer needs and preferences. Remember, continuous market validation throughout your product’s lifecycle is crucial to ensure alignment with evolving customer demands and market dynamics.

-

Test Prototypes: Create high-fidelity prototypes that closely resemble the final item. This stage is an opportunity for detailed user testing, allowing you to assess usability and functionality. Engaging users during this phase provides invaluable feedback that can guide further refinements. It’s important to note that high-fidelity prototyping is more detailed and interactive, closely resembling the final item.

-

Refine Based on Feedback: Analyze the feedback collected during user testing and make necessary adjustments to your offering. This iterative method is vital; integrating user insights can greatly improve the chances of your offering’s success in the market. As Martin Burgener, Product Director at eDreams, stated, “We tested if people valued flexibility. The first reaction from people was ‘I’m paying this because I want to go to Rome, why would I want to cancel?’” This highlights how crucial it is to understand customer perspectives during the validation process.

-

Assess Compliance: Ensure that your item adheres to any regulatory requirements specific to your industry. We recognize that compliance can feel daunting, but it not only safeguards your business but also builds trust with potential customers.

-

Launch a Pilot Test: Before a full launch, consider launching a pilot test to gather real user feedback and data collection. This step is crucial for refining your offering based on actual user experiences, and it can provide the reassurance you need as you move forward.

By following these steps, you create a strong validation process that enhances your offering’s preparedness for the industry. Case studies have shown that utilizing best practices in validation—such as early prototyping and iterative testing—significantly enhances the likelihood of success in the industry. For instance, the case study titled “Product Validation Best Practices” illustrates how identifying customer needs, prototyping early, and iterative testing can lead to successful outcomes.

Statistics indicate that products validated through thorough market research and user testing are more likely to meet customer expectations and achieve commercial viability. Remember, you are not alone in this journey; taking these steps can lead you toward a more successful outcome.

Conclusion

Navigating the complexities of product manufacturing can feel overwhelming, but you are not alone. Understanding key concepts and executing strategies effectively is crucial. From mastering the manufacturing process to securing funding and validating market readiness, aspiring manufacturers possess the essential tools to transform innovative ideas into successful products. The journey begins with identifying a problem and conducting thorough market research, ensuring that each product concept is relevant and meets consumer needs.

As the process unfolds, effective design and prototyping play a pivotal role in refining product ideas. Remember, a detailed business plan lays a solid foundation for operational success. Securing funding through various avenues—such as personal savings, loans, or crowdfunding—is vital for turning your vision into reality. Additionally, finding the right manufacturing partner and establishing clear terms enhances collaboration and efficiency, ultimately leading to a successful market launch.

In this rapidly evolving industry, embracing these steps not only fosters creativity and innovation but also prepares you to adapt to emerging trends and challenges. By prioritizing strategic planning and continuous validation, you can confidently embark on your manufacturing journey, transforming aspirations into tangible achievements. Yes, the path may be complex, but with the right knowledge and approach, success in the competitive manufacturing landscape is well within your reach. Take a deep breath, and remember, each step you take brings you closer to your dreams.

Frequently Asked Questions

What is the manufacturing process?

The manufacturing process is a journey that transforms raw materials into finished goods through stages including conception, design, production, and final assembly, ensuring the end product meets market demands and quality standards.

Why is supply chain management important in manufacturing?

Effective supply chain management is vital as it influences production efficiency and cost-effectiveness. Companies that optimize their supply chains can achieve significant operational performance improvements, including a reported 20% reduction in operational costs.

What role does quality control play in manufacturing?

Quality control involves systematic methods to ensure products meet specific standards throughout the manufacturing cycle, not just at the end. Companies that prioritize quality often see a 30% increase in customer retention rates.

What is the purpose of prototyping in the manufacturing process?

Prototyping allows manufacturers to create preliminary models to test and refine designs before mass production. It helps identify potential issues early, saving time and resources, with a typical ROI of 74% reported within two years for organizations that use prototyping.

How can adopting AI in production benefit manufacturers?

Organizations that incorporate AI in their production processes also report a 74% ROI within two years, demonstrating the financial advantages of modernizing production methods.

What initial steps should aspiring producers take to develop their concept?

Aspiring producers should identify a problem to address, investigate the industry for gaps in current offerings, define their target audience, and create a concept statement outlining the purpose and unique selling points of their offering.

Why is it important to understand market needs when developing a product?

Understanding market needs is crucial because nearly 70% of new items fail due to a lack of market demand. Identifying and addressing specific needs increases the likelihood of success.

What resources are available for enhancing skills in managing product offerings?

Individuals can enhance their skills through resources like the free Mobile App Management Certification course, which provides essential knowledge and tools for success in managing offerings.

How can geopolitical factors affect the manufacturing market?

Geopolitical factors, such as trade tensions and conflicts like the Russia-Ukraine war, can impact the manufacturing market, making it important for aspiring manufacturers to stay informed about these developments.